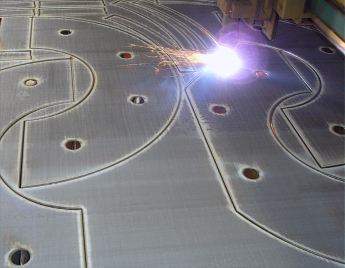

MetFab offers both manual and CNC plasma

cutting services. We utilize Thermal Dynamics cutting systems for all of our

plasma cutting operations. Thermal Dynamics has been the industry leader in

plasma cutting systems and equipment for over 50 years.

Our CNC

plasma cutting table offers a full 72” x 144” cutting area for

all of your profile cutting needs. We can cut both ferrous and non-ferrous

materials from thin gauge to 1” thick, at speeds up to 500 inches per

minute. Additionally, we can cut expanded metal and perforated sheet.

Automatic

plasma torch height control allows the system to maintain precise torch to

plate distance while cutting, no matter what the travel speed. The result is

premium cut performance, high quality surface finishes and small heat affected

zone. Positioning accuracy is ±.030” with repeatability at

±.015”.

In addition, our system has an air scribe head for

marking part numbers, job numbers or bend lines. We have fully automated

nesting software for maximizing sheet and plate utilization. We can cut your

parts from your .dxf files or can create drawings in house. All of this means

high quality parts, excellent materials yield and faster processing time for

you our customer.

|

|

| • |

|

Cuts any geometry—straight cuts, holes, and

contours |

|

|

|

| • |

|

Small heat affected zone |

|

|

|

| • |

|

Both ferrous and non-ferrous materials |

|

|

|

| • |

|

Full 72” x 144” cutting area |

|

|

|

| • |

|

Materials from gauge to 1” thick |

|

|

|

| • |

|

Smooth, high quality cutting edge finishes |

|

|

|

| • |

|

Air scribe capabilities |

|

|

|

| • |

|

Parts produced form your drawings or, in-house CAD

drawings |

|

|

|

|